How To Do a tubeless conversion

Tubeless Technology

This is a world of ever-changing wheel sizes and standards for hub spacing. Thus, it makes sense to join the expanding biking community of going tubeless. After all, the biking community agrees that tubeless is certainly a useful piece of technology. This is not just a marketing hype, and one will come across different tubeless technologies available. What you need is information on how to converting from tube to tubeless. Read on to know more on how to convert to a tubeless setup from your standard tire and wheel combo.

Drawbacks of traditional system

The traditional combo of tire and tube has always been there and has no doubt served us well. However, the system comes with its drawbacks. This is because the tube is always a lot more vulnerable to those thorns, rocks and nails lying on the roads. Moreover, nothing can be more annoying than to see that flat tire and your bike coming to a complete halt. All it needs is a tiny shard of rock or a thorn or that nasty nail to bring that mighty high-tech mountain bike down its knees. The solution lie in turning to tubeless setups and keep those troubles at bay.

However, not all wheels and tires are made keeping those aspects in mind. Thankfully, there are many kits that can help convert the standard wheels and tires to no tubes. The tubeless wheels carry a sealed rim, and thus the air cannot escape through the valve holes or spoke. When the tire is inflated, the air pushes the lower edge of the sidewall into the matching hook of the rim bead, thus resulting in an airtight seal. The benefits of turning tubeless are immense. Apart from keeping those nasty flats away, the lower pressure and low weight offer more grip. Turn to the tubeless setup and see those penetration punctures become a distant, faded memory.

Which Tubeless Kit Is Right?

Tubeless systems have led to the development of a market for going tubeless, and it is no surprise to see a high demand for those Tubeless Kits that can make ordinary wheels airtight. The apparent advantage of tubeless tires is making the road riders increasingly adopting the tubeless tires for their bike. The basic principle that works here is to create an airtight seal separating the rim of the wheel and the bead of the tire minus the presence of an inner tube.

Tubeless conversion kits consist of a rubber rim strip and liquid sealant that help create an airtight seal. These kits are used to change ‘ordinary’ tubes and tires to tubeless. If one already has tubeless-ready rims and tires, the conversions are easy and inexpensive. Otherwise, it may take some efforts and practice to get things right. Tubeless-ready tires do not carry an additional airtight layer and rely on the liquid sealant to prevent air escaping.

When picking a tubeless conversion kit, make sure to match the included rim strip to the size of the wheels. The rims may come in different diameters and vary in width for various applications. The Tubeless Presta Valve Stems from WISTIO carries a removable valve core for easy inflation, a large vulcanized rubber base that fit most rims perfectly and plastic screw on valve cap. The customer gets options for color in Alloy made or Brass made presta valves. High-end mountain bikers prefer Alloy to Brass as they are looking for a lightweight option.

How to convert your standard tire into a tubeless setup

It is time to learn how to convert the standard setup into a tubeless one. Remember that you may be tampering with the tire’s warranty when converting it to tubeless.

Or if you just have a Schrader valve used pump, you just need a Schrader-Presta convertor is ok. cheap & convenient.

Hold the bike in place with the wheel in. Now, clean the rim thoroughly so as to maximize the chance of creating a perfect airtight seal.

Overlap tape by about 6″ and cut with sharp scissors. The edge of tire lever should be used to make sure that tape sticks completely inside the curves of the rim bed

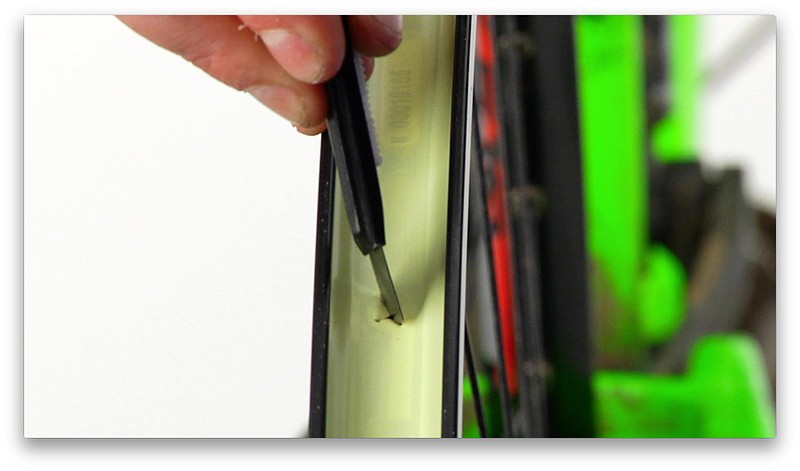

make a small cut of “X” to open the tape with the help of a sharp knife that is covering the valve hole. One should be careful here so as to not to cut any extra beyond the hole and what is required.

Install the tubeless valve stem carefully and tighten it with the help of the lock nut to make it secure and tight.

Certain tire and rim combos inflate fast with only a pump while others may need some soapy water or a compressor to seal

Keep the wheel in the same position and use both hands to install the bead consistently around the tire

Many experts suggest a quick blast of. However, it is advisable to do a ‘test inflate’ first. If there is air escaping, it indicates a porous area. Use the liquid sealant after deflating the tire. Re-inflate the wheel and rotate and bounce it to ensure an equal and even distribution of the sealant that has been poured in. One should inflate the tire to the ended pressure. Once your bike goes tubeless, you are sure to feel the difference when you ride it. The tires grip much better, and you can get maximum performance without worrying about those thorns, pinch flats, etc. The ride is going to be much smoother and with almost nil vibration and shaking. Lighter rotational weight adds to the fun.

Oderus: I have a feeling you are cocrert. I see the tubeless ready concept as the reason for the seeming delay in new tires not only from Geax, but from several other manufacturers as well. It just doesn’t make sense to introduce a folding bead tire anymore. It has to be a tubeless ready product, and this also eliminates the need for a separate UST type carcass that holds air without sealant. One new tire model that can be used tubed or tubeless. Once the manufacturing processes catch up, I think we’ll be seeing a lot more tires from Geax and a few others as well.